What we produce

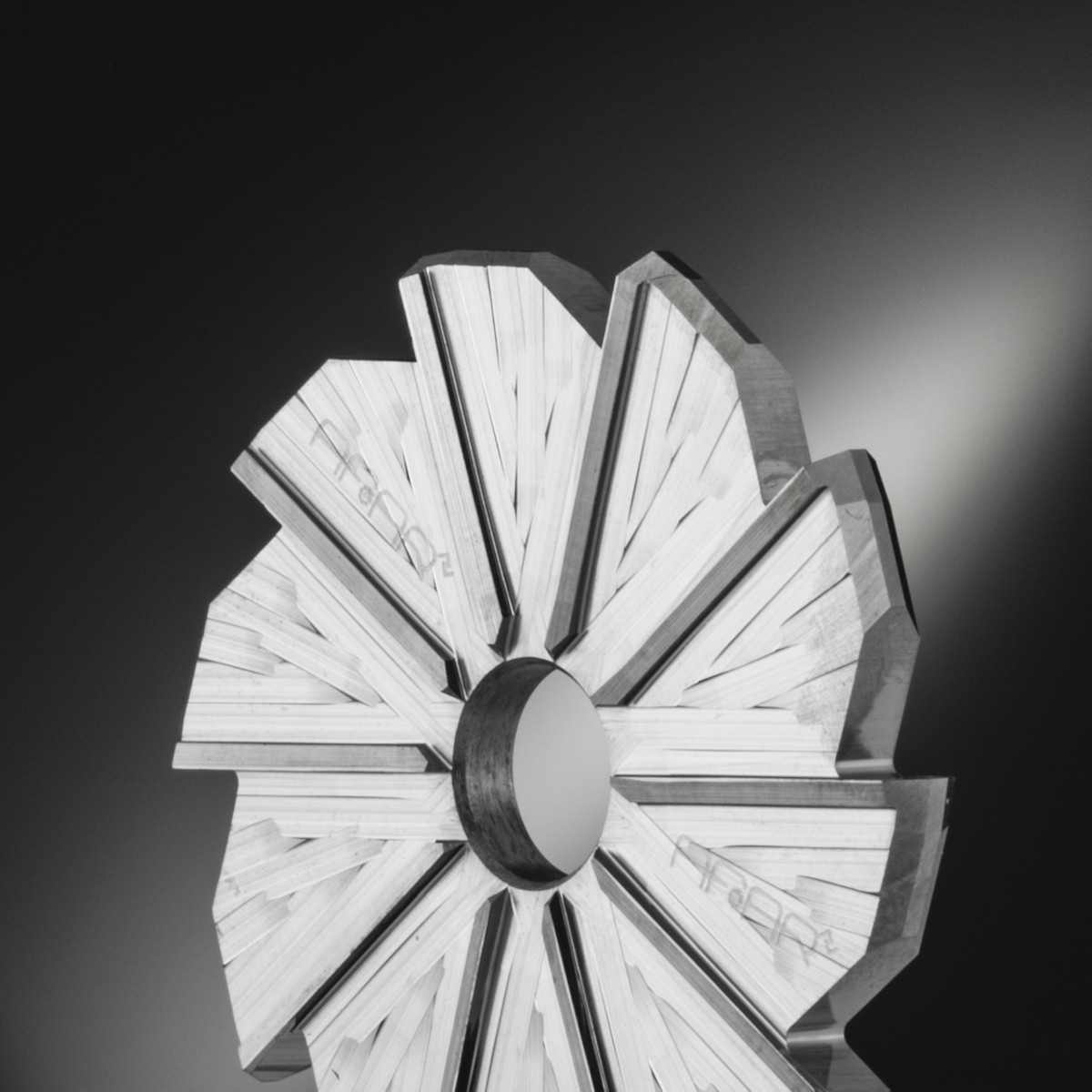

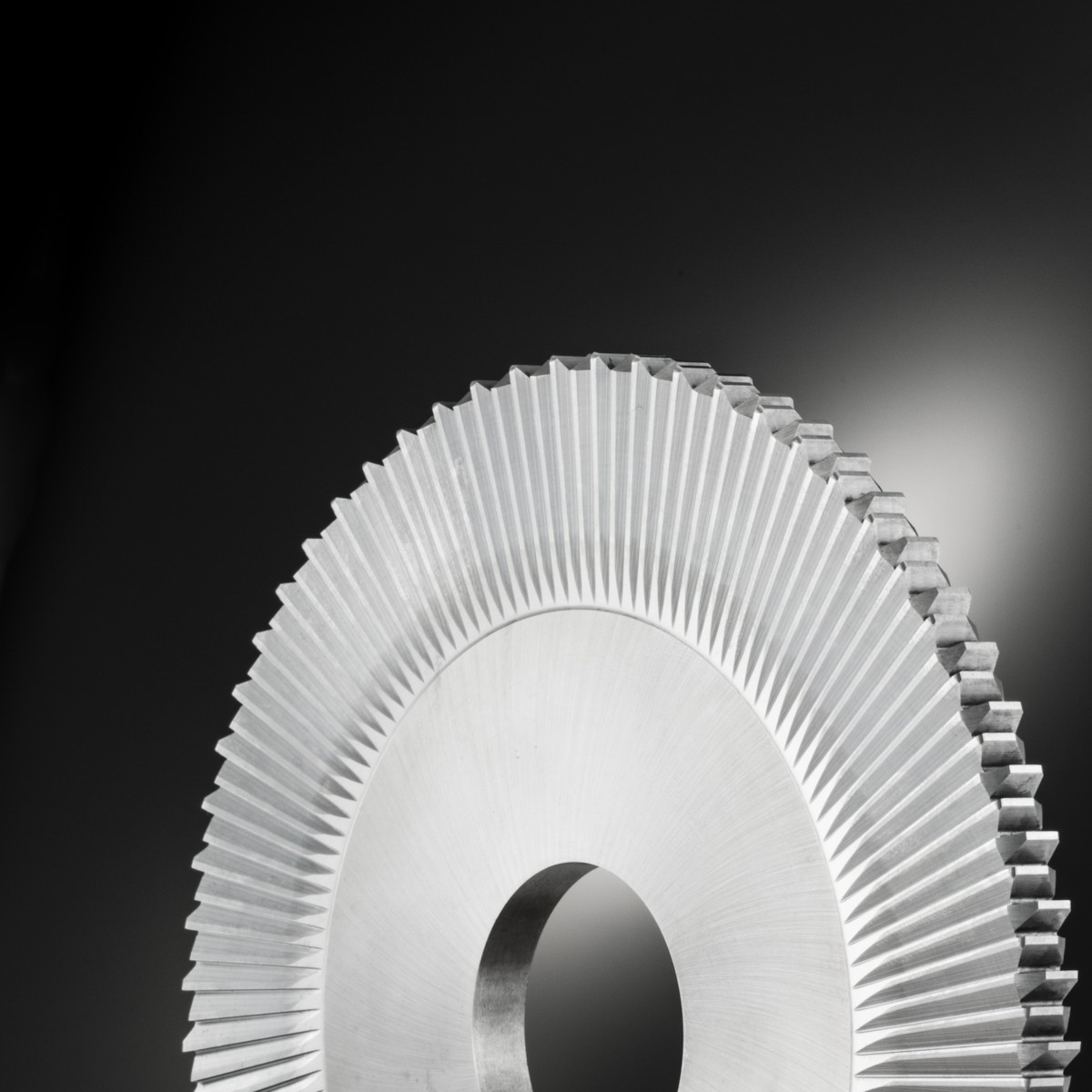

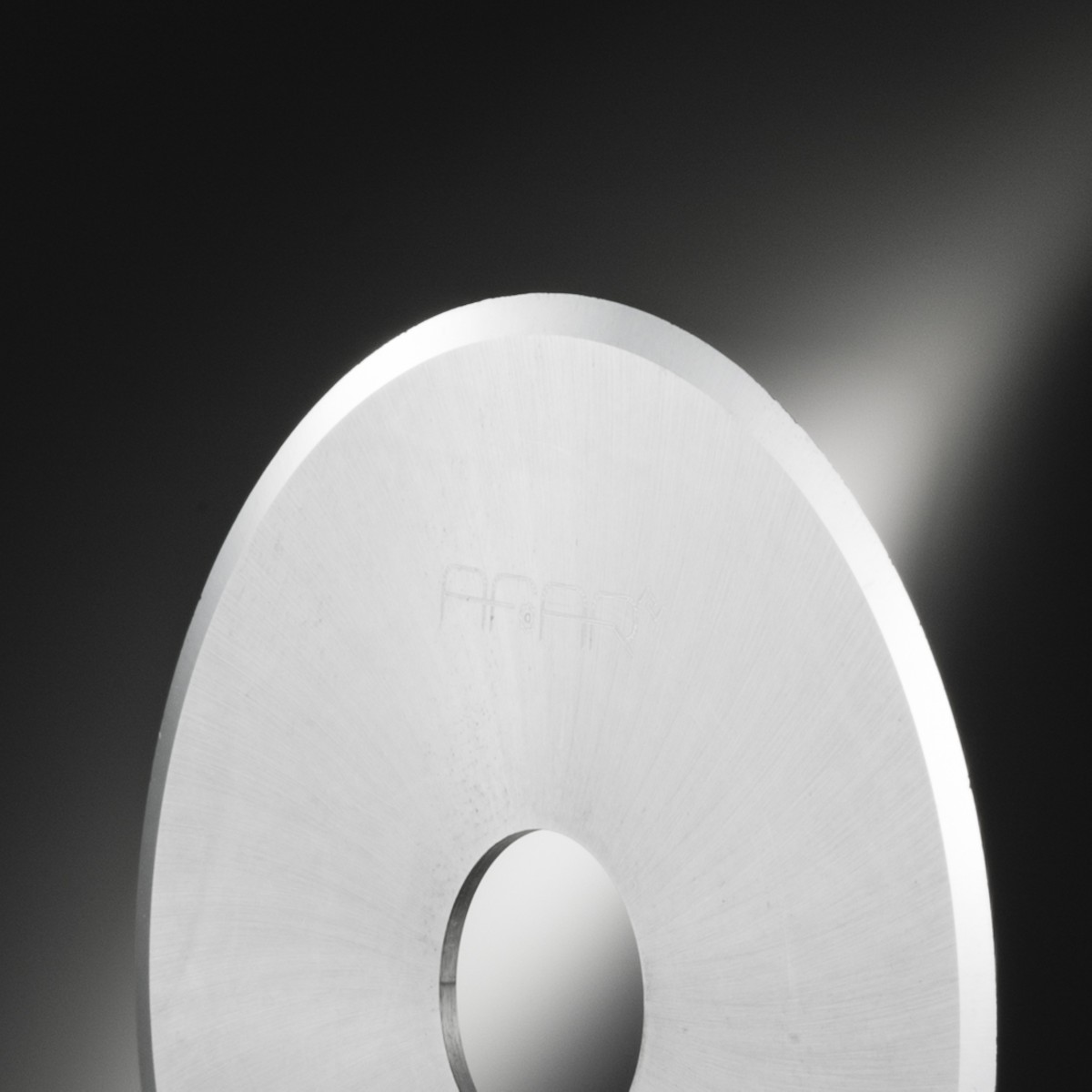

AF.AR produces drills and circular saws carbide.

The integral circular saws are the point of our production strength, the space dedicated to this highly qualified tool and specific, up more than 70% of our production efforts.

They are produced starting from a diameter of 6mm up to 250mm and a thickness of from 0.2mm up to 6mm.

We can produce more low thickness or higher according to customer specifications.

With the increase of the external diameter (for obvious reasons of fragility) decreases the minimum construction thickness.

From AF.AR you find the teeth according to DIN 1837 and DIN 1838, but we can produce saws and cutters with any type of dentition (extra fine, extra wide, helical, altrenata, straight-etc.) Or the customer’s specific request based on material to work with and the conditions of use. The outer walls may be parallel, lowered until hole or with a central body (hub) of the exterior of the same thickness.

Carried out integrally on numerical control machines, in the various types and forms, appropriately designed for singular cases with specific geometries of cutting corners and in the second of the materials to be processed, contained in centesimal tolerance normally thousandth and where it is required, both for the thicknesses that for eccentricity ‘combined with a careful selection of quality sintered they are made, our circular saws are not afraid competitions both national and foreign.

Quality

Our saws and drills are available in 3 carbide grades.

- NORMAL LINE – They can be supplied in few time.

- SELECT Q LINE – They can be supplied in middle-short time

- HIGHT SQ LINE – They suggest orders by programm.

As in all fields, also in this sector there is a case study in which the user,

have built the machine to fit your needs,

providing different dimesionalmente tools.

Our experience is able to meet the need

of a tool to measure, for both cutters that for rollers.

For those who produce

AF.AR produces for various sectors, of which we list a part.

- Needle bets for knitting machines

- Cylinders for circular knitting machines

- Electrical collectors for alla shapes and diametres

- Mechanical small parts brass, bronze etc..

- Goldsmith and orthodontics using gold, silver, platinum, palladium

- Clocks (boxes, bracelets, horns, ambou etc.)

- Printed circuit boards (pre-cutting and scoring of the circuit)

- Eyewear (faces, grooves, frames)

- Cutters to a cutting edge for pantographs

- Collets and tool setting dials

- Keys and locks

- Tubes and section iron

- Cutters for cutting paper, cardboard, rubber, abrasive resins, glass, fabric, leather, wood

The our customers benefit from our comprehensive service direct regrinding.

Fields of employment

Applications range in the most varied and sometimes more unthinkable productive sectors of which we can name a few of the most significant.

- Needle bets milling

- Milling calender

- Commutator milling

- Lamellae milling

- Resins and composite material cuttng

- Precutting and cutting of saws

- Lamellae cutting for transformers

- Small tubes for goldsmiths

- Rubber cutting and milling

- Milling and cutting of particulars for glasses

- Keys milling

- Screw hesds cutting etc.

We mentioned now the most common cases of employment, but the extent and flexibility of utilization is hingher and not always identifiable.