About us

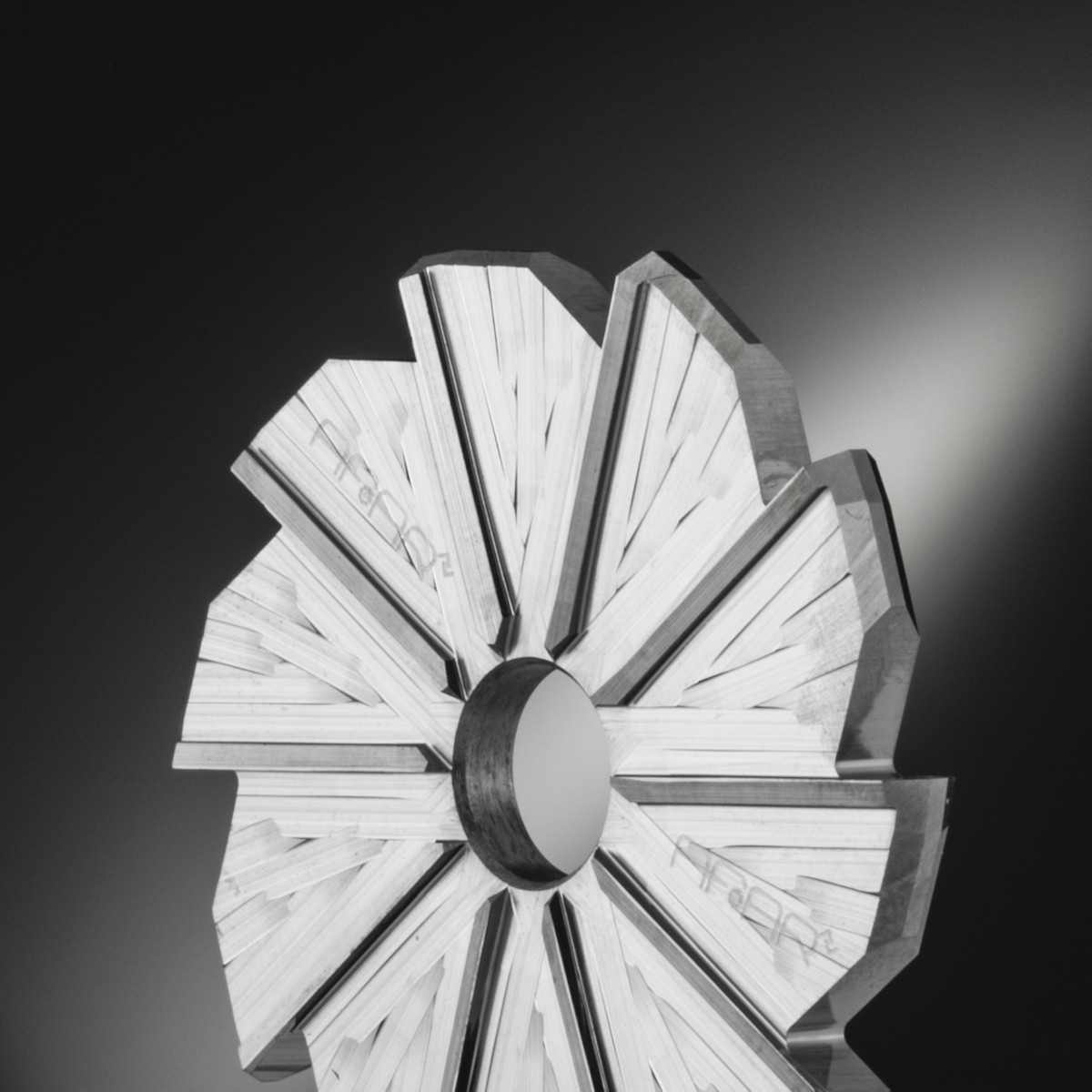

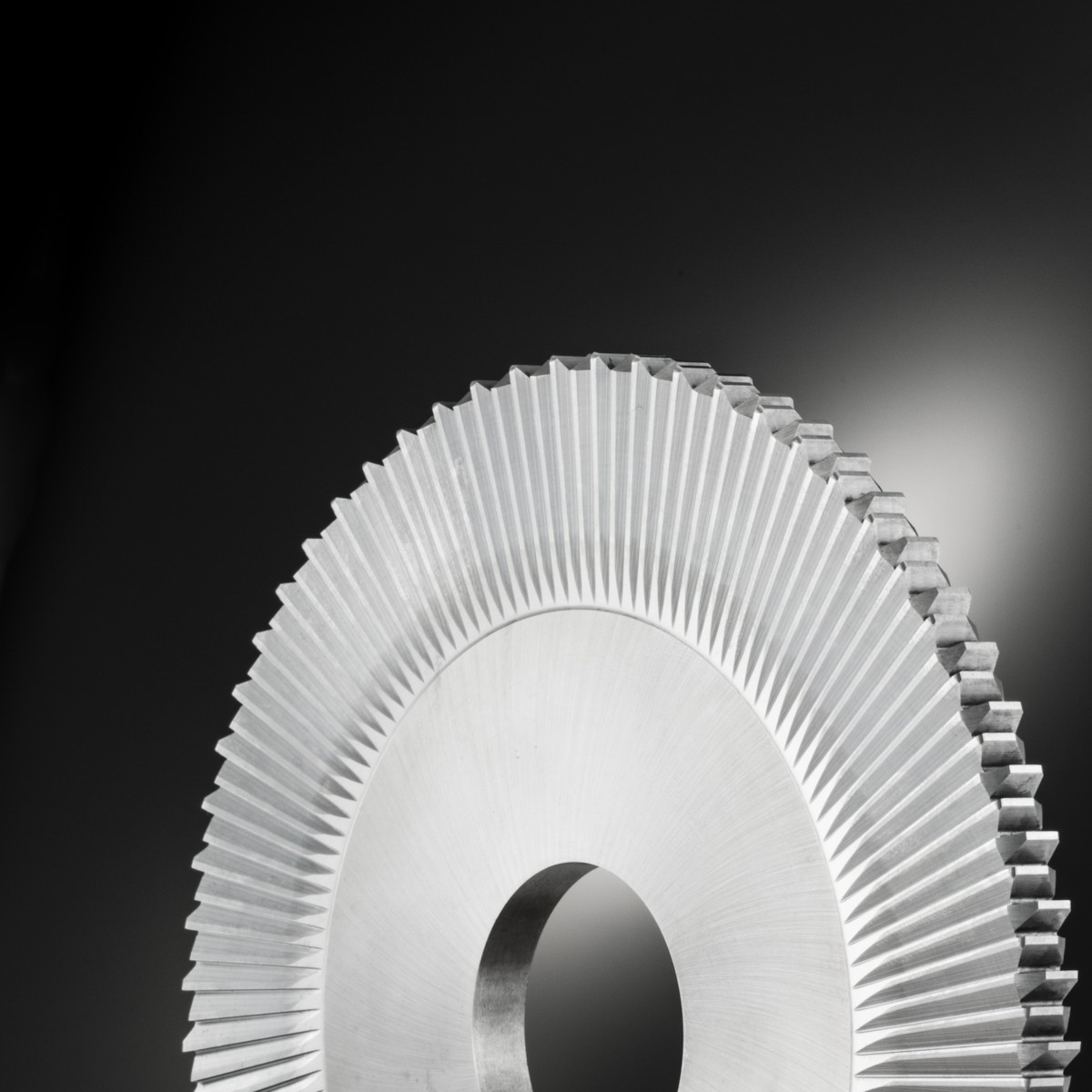

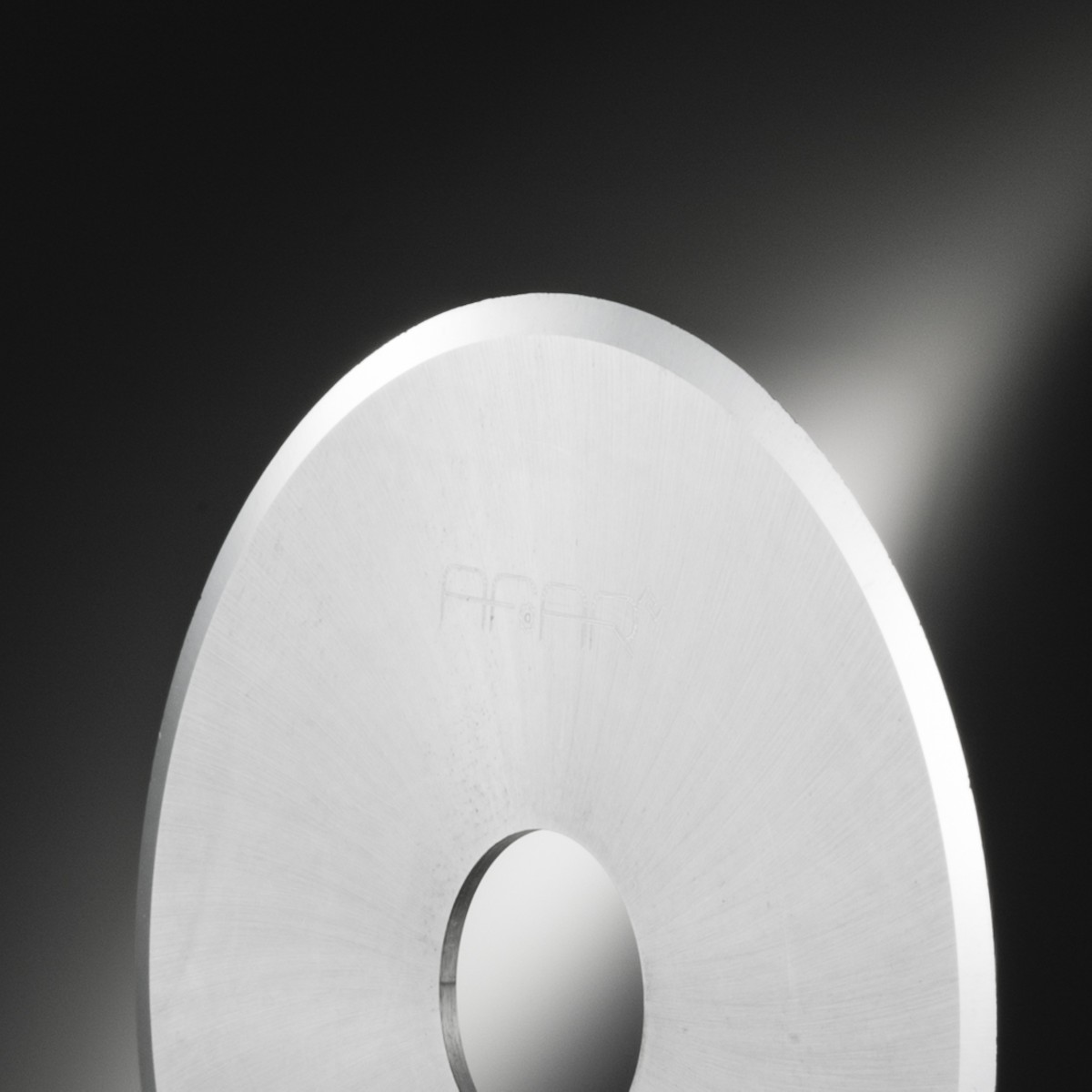

AF.AR circular saws carbide

AF.AR, teamwork

AF.AR employs highly qualified and skilled personnel. The team is structured in a simple and straightforward organisational chart to ensure the highest level of satisfaction of customers and the evolving market.

AF.AR‘s front line experience and daily commitment over the years, has allowed us to create a complex and comprehensive system of management of production, logistical and management processes at all levels.

Who thinks to have a future copying from the others and thinks that pressing a button everything is possibile, must know that a firm and its professionality don’t improvise, but they grow together with honesty and a daily experience of who is part of it.

Maurizio Bassetti

Our story

1982

Maurizio Bassetti with the crucial support of his father Luigi founds AF.AR Affilatura Artigiana a company that regrinds solid carbide milling cutters and circular saws for WATCHES - JEWELLERY - EYEWEAR - MANIFOLDS - MECHANICAL-TEXTILES.

1983

The workshop is upgraded with the purchase of one of Italy's first numerically controlled universal grinding machines. We buy our first grinder and modify it for the production of discs for circular saws and milling cutters. START OF PRODUCTION OF SOLID CIRCULAR SAWS.

1984

Purchase of the second numerically controlled grinding machine and installation of two specific grinders. This is the year of the first catalogue which launches the sales network.

1985

The first 250 mm diameter blades are produced and the production range is completed with PRINTED CIRCUIT cutters. This year some products are exclusively assigned to a firm that SELLS PRODUCTS under its own brand. This partnership lasts for almost 15 years.

1986

Introduction of the control and historical identification of sintered items along with self-certification. From this point the history of each item can be accurately reconstructed even after many years.

1987-1998

Introduction of sophisticated CNC machines and adoption of advanced CAD - CAM for production systems. Introduction of a powerful database specifically for the production and design data storage system. The first Afar-Tools.com website goes on line.

1999

Our agreement with the outside firm expires. We decide to set up a direct sales network for the domestic and foreign market with the AF.AR. TRADEMARK.

2000

Relocation of headquarters to the new site.

2003

Introduction of CNC plane grinding machines with new technology.

2005

Launch of the second grinding shop for the bodies of circular saws

2006

Introduction of high power CNC grinding machines with fully automatically loading measurement cycle for high production. Introduction of a robotic system for laser printing on the other series.

2007-2011

Strengthening of the grinding department with new generation loading machines, at the end of 2011 there will be 5 of them with a production capacity of 50,000 circular saws per month.

2012-2019

Installation of new generation cad cam sharpeners with automatic loading of pieces and grinding wheels, the metric room is enhanced with new optical measuring machines.

2019-2021

Expansion of the production area on an area of 1300 square meters. - Installation of other grinding and sharpening machines with automatic loading.

2022

Opening of the restaurant with private kitchen inside the headquarters to host friends, customers and suppliers.