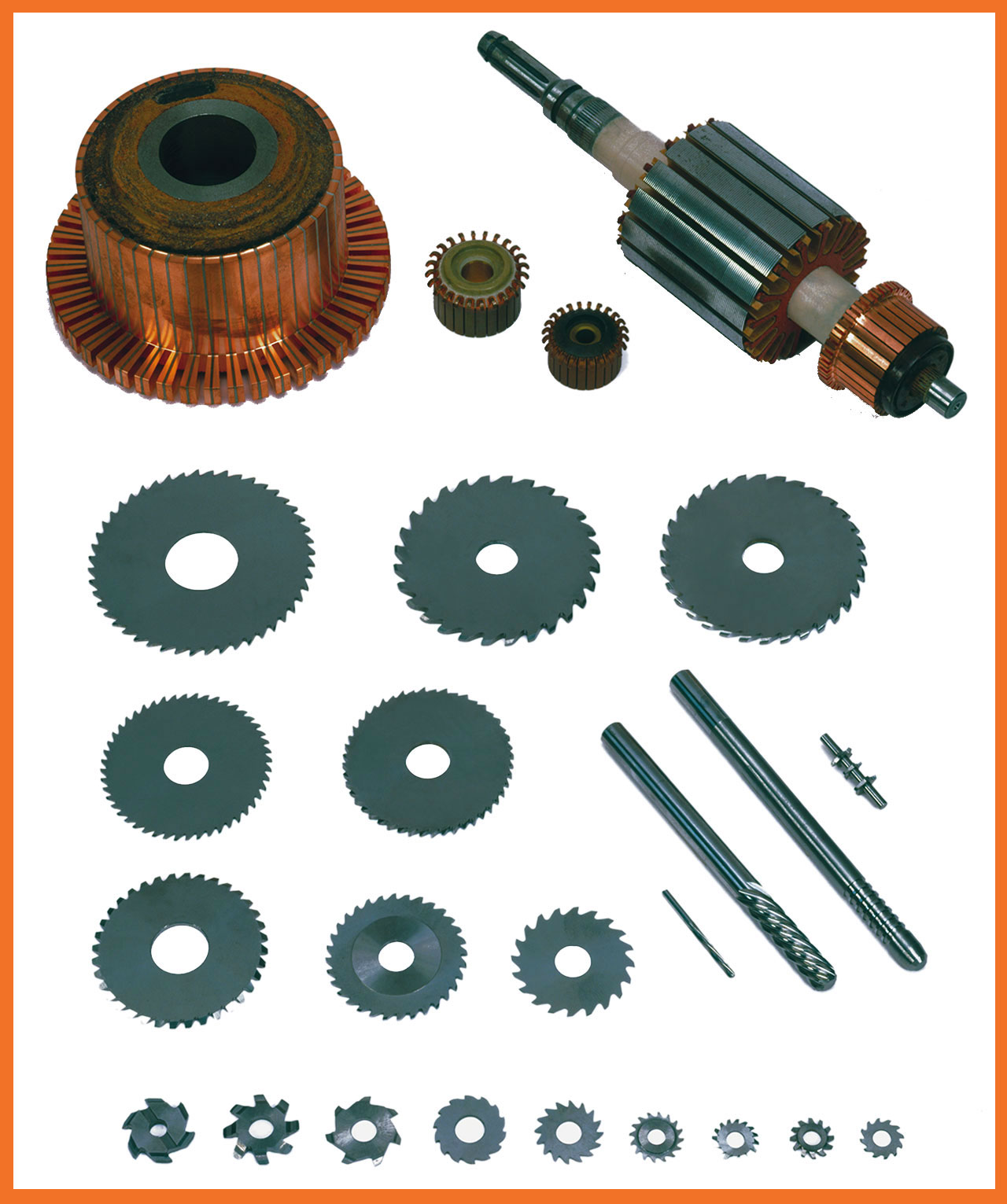

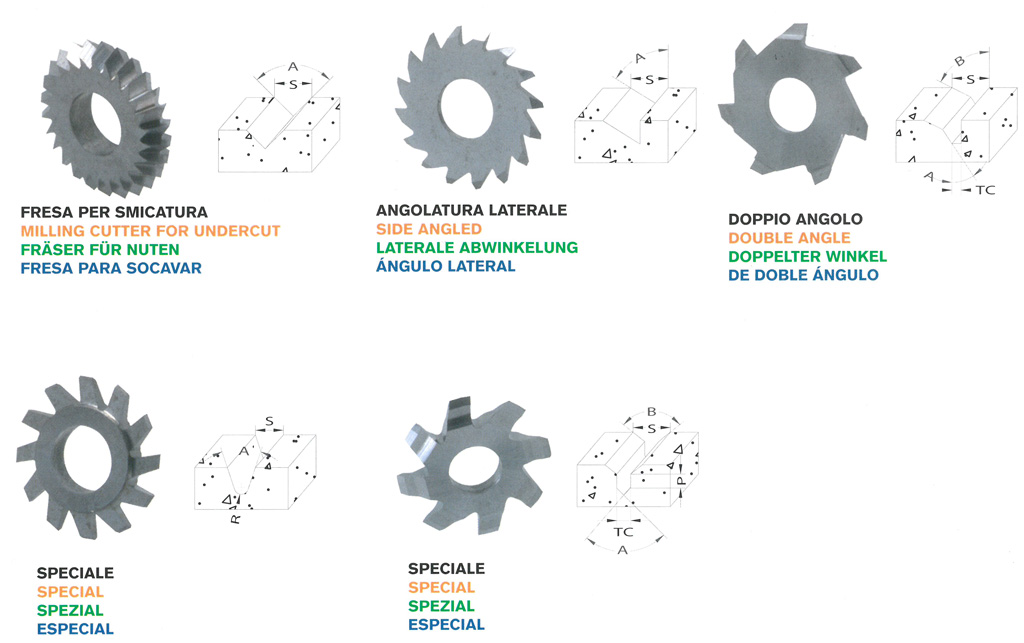

Mills for enginess and commutator electro-mechanics

They are employed for manual and/or automatic machines for works of milling, undercut of small and medium commutators, for production and maintenance; the same milling cutters of a superior diameter can be used for particular works of bigger dimensions.

They are usually constructed by request of customer on the ground to diameter/hole/teeth number and angle-shots

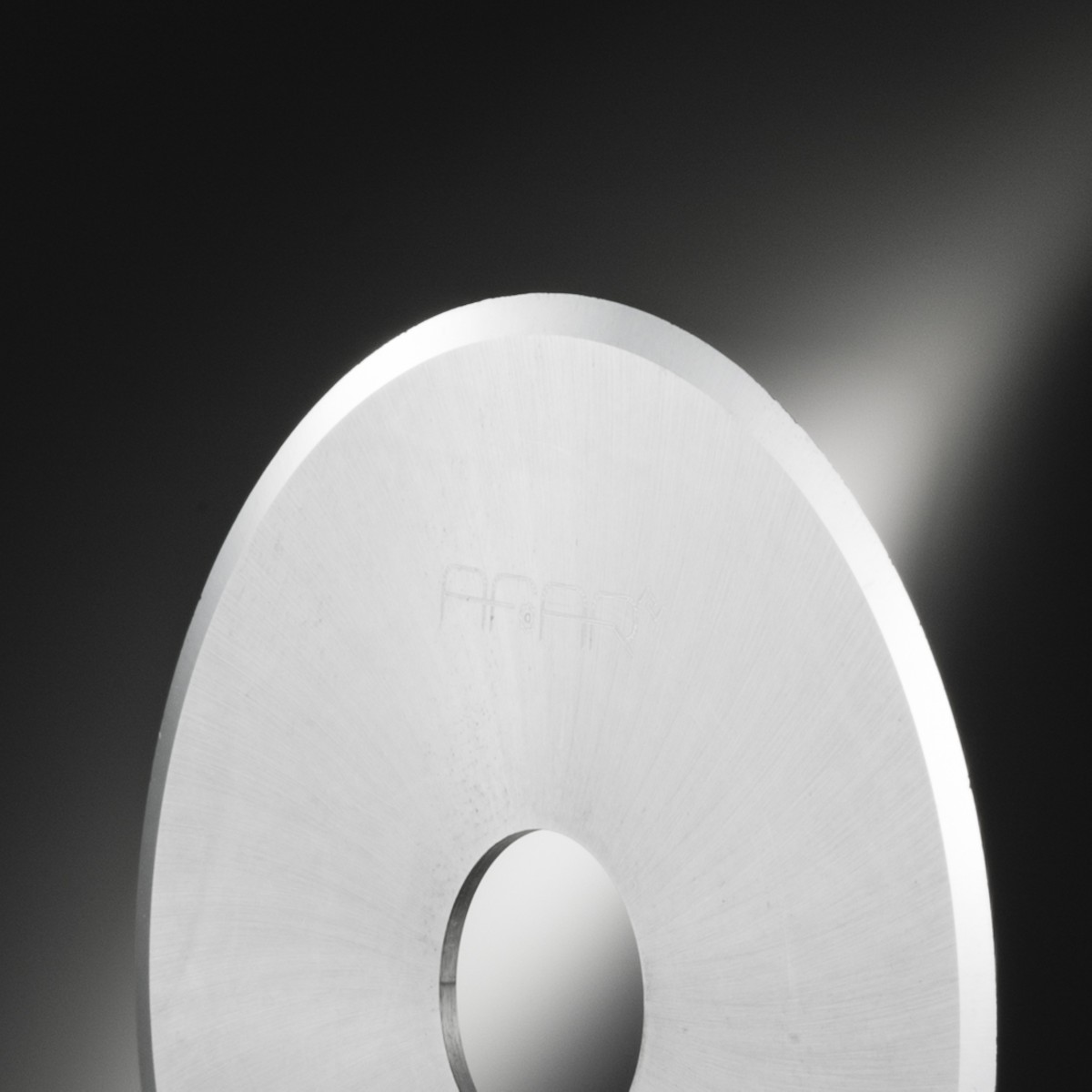

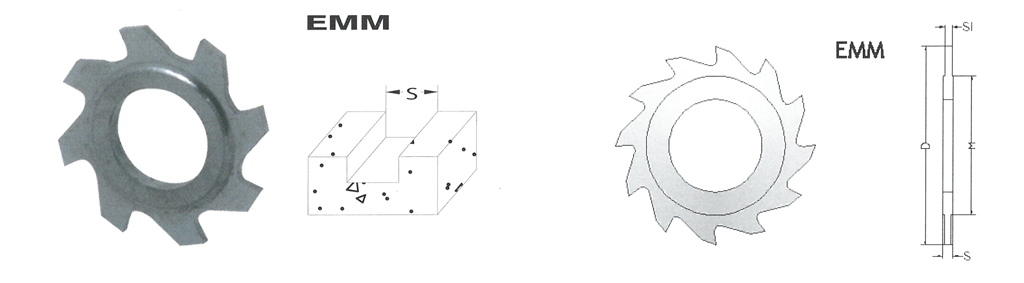

Reinforced mills

| D | F | M | S1 | S | Z | |

|---|---|---|---|---|---|---|

| EMM10 | 10 | 3 | 6 | 0.3-1.0 | 1.1 | 10 |

| EMM15 | 15 | 5 | 7.5 | 0.4-1.0 | 1.1 | 16 |

| EMM21 | 21 | 7 | 10 | 0.4-10 | 1.1 | 20 |

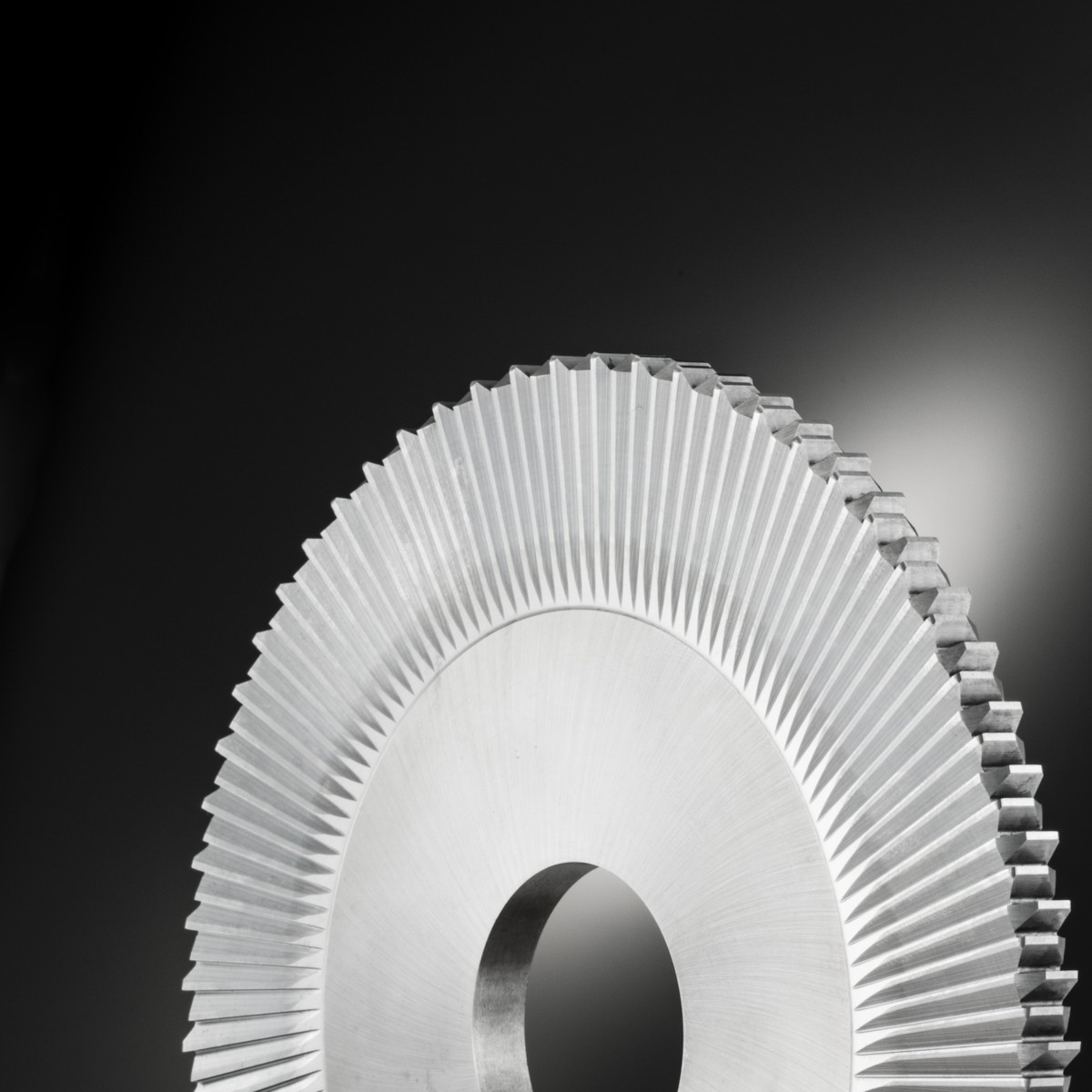

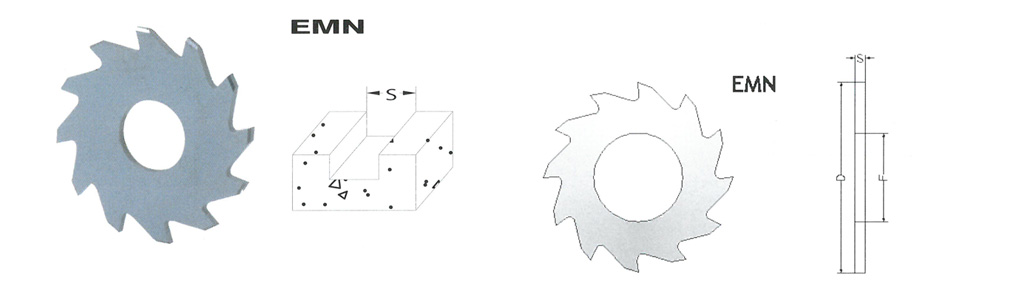

Standard mills

| D | F | S1 | Z | |

|---|---|---|---|---|

| EMN32 | 32 | 8 | 0.3-2.0 | 24 |

| EMN35 | 35 | 10 | 0.4-1.0 | 20 |

| EMN40 | 40 | 10-16 | 0.4-2.8 | 24-32 |

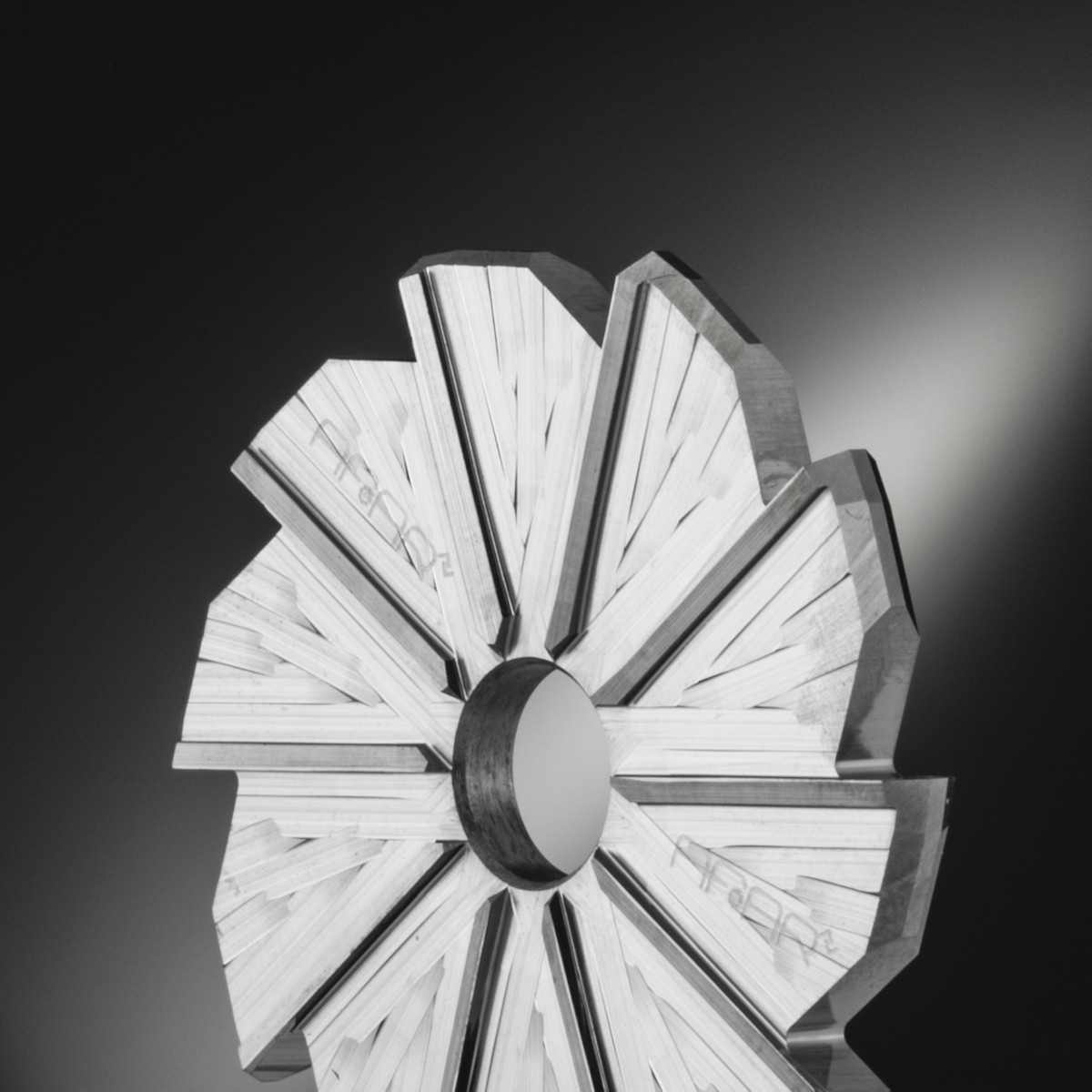

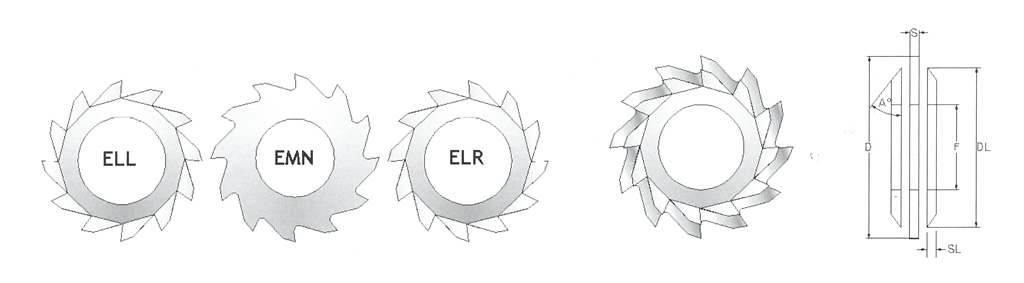

Mills in group

| D | DL | F | S | SL | Z | A° | |

|---|---|---|---|---|---|---|---|

| EMN10 | 10 | 3 | 0.4-1.0 | 6 -10 | |||

| ELL10 | 8.5 | 3 | 1 | 6-10 | 45° | ||

| ELR10 | 8.5 | 3 | 1 | 6-10 | 45° | ||

| EMN15 | 15 | 5 | 0.4-1.0 | 10 | |||

| ELL15 | 13.5 | 5 | 1 | 10 | 45° | ||

| ELR15 | 13.5 | 5 | 1 | 10 | 45° | ||

| EMN21 | 21 | 7 | 0.4-2.0 | 12 | |||

| ELL21 | 19 | 7 | 1 | 12 | 30° – 45° | ||

| ELR21 | 19 | 7 | 1 | 12 | 30° – 45° | ||

| EMN25 | 25 | 7-8 | 0.4-2.0 | 20 | |||

| ELL25 | 23 | 7-8 | 1 | 20 | 45° | ||

| ELR25 | 23 | 7-8 | 1 | 20 | 45° |

“V” mills

| D | F | S | Z | A° | |

|---|---|---|---|---|---|

| EMV12 | 12 | 5 | 0.4-1.0 | 10 | 20° |

| EMV15 | 15 | 5 | 0.4-1.0 | 12 | 20° |

| EMV21 | 21 | 7 | 0.4-1.8 | 16 | 20° |

| EMV25 | 25 | 7-8 | 06.-2.0 | 20 | 20° |